CABE srl, based in Italy, is a company specializing in the production of aggregates of various sizes and types for the building industry. In 2020, the total production of the “Ripa Calbana” quarry, located in the municipality of Borghi (FC), increased significantly and the customer decided to contact Diemme® Filtration for the purchase of a second filter press – one had already been operating in the same plant since 2013. A new GHT2000.P13 filter press was selected.

The excellent relationship of trust and cooperation established over the years between CABE srl and Diemme® Filtration srl was the basis for a renewed partnership under the banner of innovation.

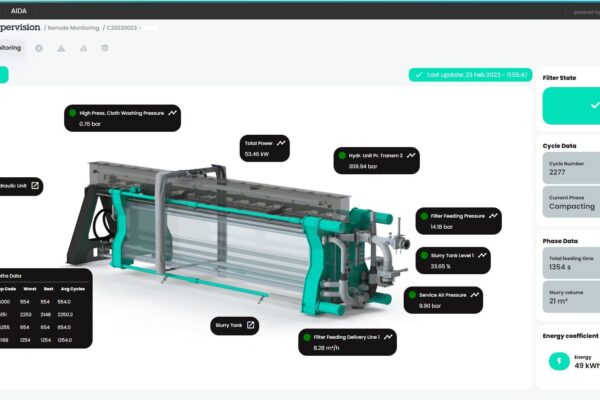

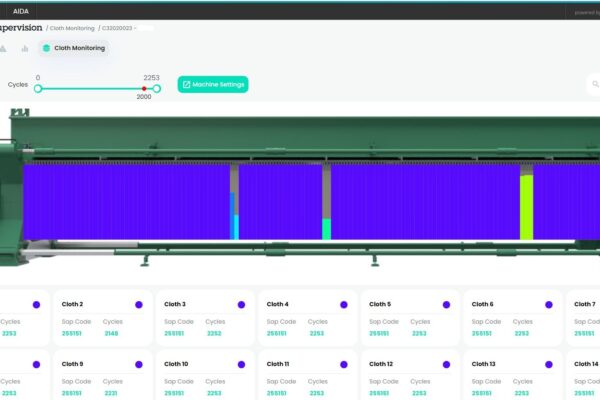

Diemme® Filtration responded to CABE srl’s increasingly stringent requirements for a reliable, efficient and economically and environmentally sustainable plant with an innovative IIoT proposal: AIDA Service, a remote monitoring system tutor.

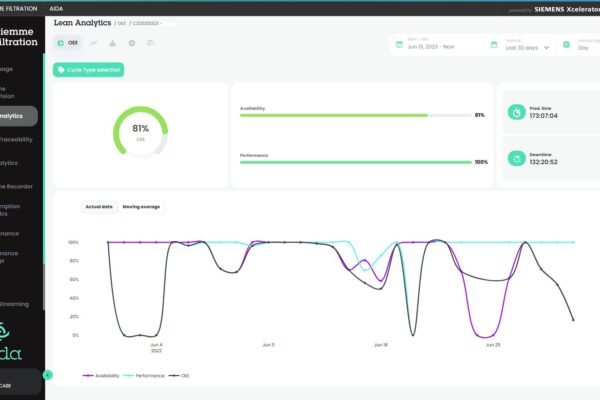

CABE srl became the first Diemme® Filtration partner to activate the AIDA Service and, thanks to the technological and engineering solutions adopted, in more than two years of operation it has managed to reduce downtime due to unplanned stops, prevent breakdowns, improve spare parts management and reduce consumption, especially of water, thus achieving optimised closed-loop plant management.

In particular, it has been possible to:

- Avoid damage to the feed pump electric motor by monitoring and analysing abnormal power consumption;

- Reduce the energy consumption of the compressor used for core blowing by analysing the consumption when the plant was in stand-by mode;

- Achieved 98% plant productivity.

The remote connection was the key to this success. This, combined with the constant supervision of our experts and the company’s know-how, has enabled Diemme® Filtration to take a further step forward in the solid/liquid separation industry.