In recent years, the steady increase in the complexity and size of projects has required a higher degree of detail in the design phase.

For this reason, our Team of Engineers and specially trained Technicians is continuously growing and is one of the strengths of our company. Expertise, collaboration and specialization are the ingredients that enable us to successfully meet all professional challenges.

- Analysis and development of new ideas

- High-level design

- Detailed design, structural calculations and calculation reports

- Construction and assembly drawings

- Risk analysis

- Realization of mass balances and P&IDs

- Technical comparison on sizing and choice of plant components

- Technical comparison on the choice of construction solutions

- Process verification in collaboration with the laboratory

- Civil structural calculations

- Simulation of operation

- Development of operation and maintenance manuals

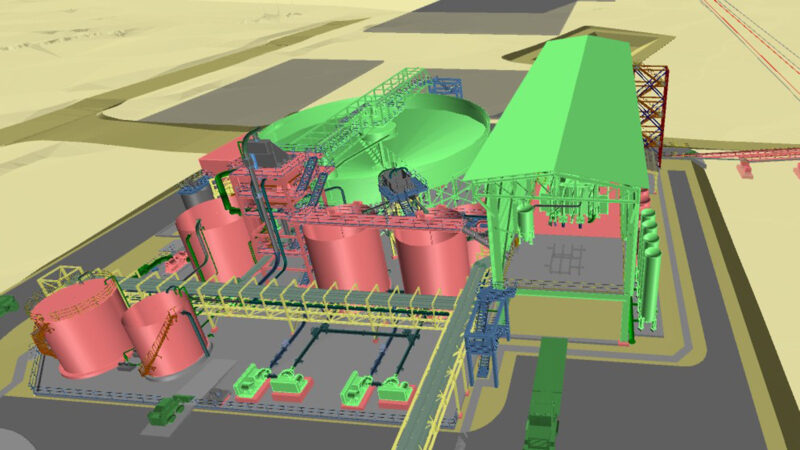

Plant rendering

During the technical review of orders, it is essential to create a 3D layout of the plant. Thanks to our augmented reality systems, we can create a virtual tour in the plant in order to verify its functionality, ergonomics and offer a set of experiences that, to date, could be done only when the plant is built.

Detailed design

In the detailed design phase, Diemme engineers focus on refining every aspect of the design, ensuring maximum precision and functionality while paying close attention to customization and required standards. Technical specifications, materials and tolerances are defined to ensure that the final product meets the needs of the individual customer.

P&ID and HMI

During the implementation of an order, our Engineering Team develops, in consultation with the customer, the P&ID of the system.

This document is a visual, clear and a detailed representation of all the piping, equipment and instruments involved. It facilitates proper implementation and operation of the system and helps to understand the entire process flow, identify any critical points, and ensure operational safety.

Installation at the plant

Installation of our solution on-site requires careful planning and coordination. With the assistance and continuous support (physically and remotely with the AIDA service) of our experienced technicians, the installation proceeds optimally, overcoming any obstacles and ensuring perfect set-up and optimized performance.