Our efforts combine and integrate high levels of multidisciplinary skills, resulting in systems that are highly innovative in four fundamental ways:

The filtration process

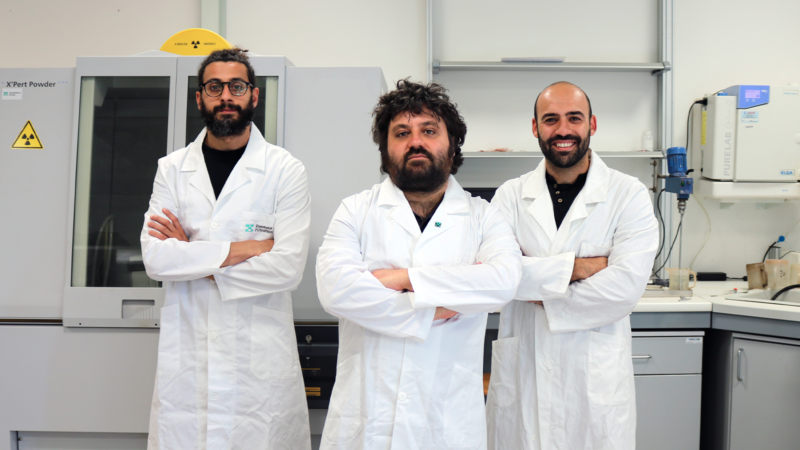

The beating heart

The team of industrial chemists and process engineers carry out in-depth characterization and accurate experiments on real samples to determine filtration and thickening parameters. Their analytical and fluid dynamic skills and mastery of customised laboratory and industrial scale experiments are essential in optimising the customer’s production process and ensuring the performance of the equipment supplied.

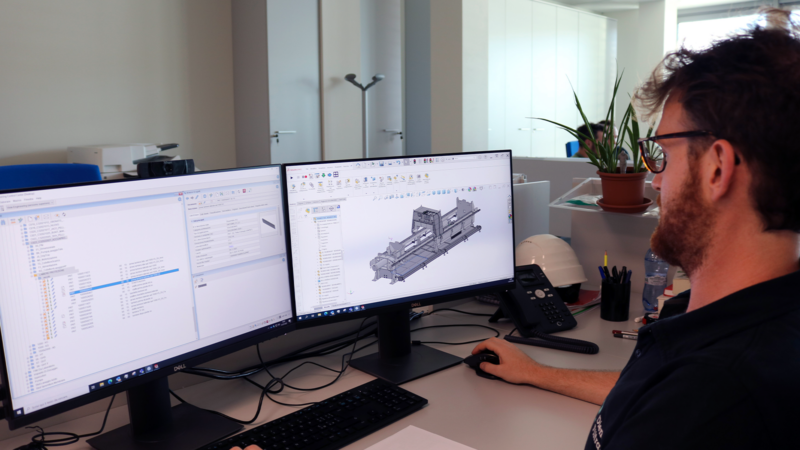

Mechanics

The skeleton

The mechanical engineering team designs new machine models, challenging the laws of statics and dynamics on a daily basis to achieve new dimensional and performance targets. Drawing on decades of experience in the operation of plants in various industrial applications, it applies its high level of expertise by verifying all the innovations introduced in the new models with static and dynamic FEM simulations, providing optimised and reliable structures to maintain performance in the long term.

Industrial automation

The nervous system

The automation engineering team is constantly looking for new solutions to improve the performance of our machines in terms of speed and adaptability to process requirements, while maintaining total flexibility. Every proposal we introduce is designed to be fully compatible with any technology supplier chosen by our customers.

Digitalisation

The thinking brain

The new team of physicists and engineers is integrating plant experience and exploring the new IIoT worlds in search of radical innovations in the development of machine learning applications, vision systems and neural network algorithms, artificial intelligence, to make our machines not only robust and powerful, but increasingly intelligent and connected.