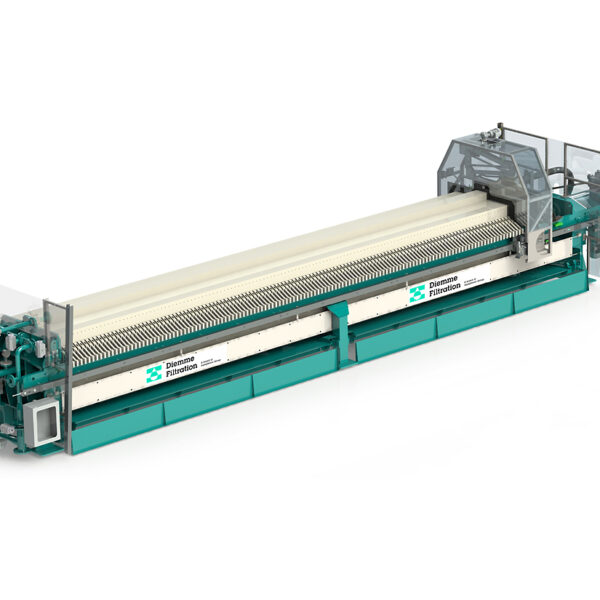

Side beam Filter Press AUTOMAT

The Diemme® Filtration AUTOMAT filter press is a straightforward and flexible machine, ideal for industrial processes that require a limited number of daily cycles and for the treatment of products with reduced filterability. A range of large and small models is available for different plant situations.

Key Points

- Plate-by-plate opening by detaching robot

- Plate shaking device option for fully automatic operation

- Simplicity of installation and use

- Automatic high-pressure washing system

- Cost-effective

- Photoelectric barriers: use of the most modern and advanced safety and operator protection systems

- PLC (HMI – Human Machine Interface)

The filter plates, sliding on the side beams of the AUTOMAT filter presses, move automatically. The operator can adjust the speed of the plate opening according to the product behaviour.

- Plate-pack closing system uses a single “push to close” cylinder

- Fixed and/or photocell side protections ensure operator safety

- To increase the level of automation, the plate shaking system (available from size 1.000 x 1.000 mm to size 2.000 x 2.000 mm) allows automatic cake detachment

- An automatic high-pressure cloth washing system refreshes cloth porosity

- PLC (HMI – Human Machine Interface)