In inert building materials production and treatment plants, often known as “Quarries”, many processes applied to the excavated material are wet processes (e.g. washing, vibrating screening, hydro-cycloning, etc).

Downstream of the various stages, the wash waters, which constitute a waste, accumulate a quantity of fine clayey material (cyclone overflow with particle sizes below 75 microns) which constitutes a thickened sludge. In these installations, one of the main objectives (from an economic and environmental point of view) is to recover as much water as possible and return it to the wash plant.

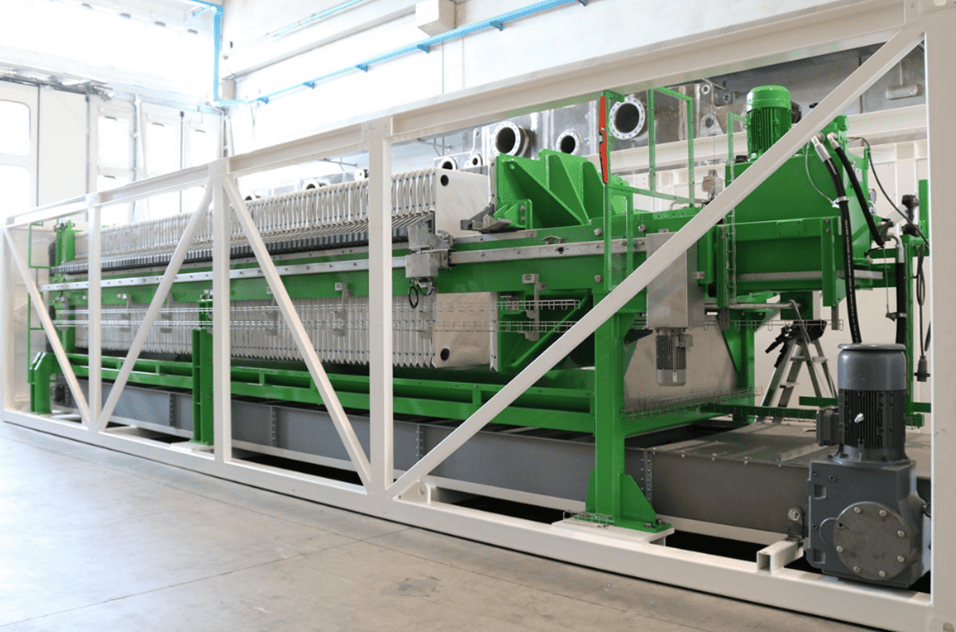

Dewatering with a filter press allows the greatest recovery of water and reduction of the volume occupied by the discarded solids. Diemme® Filtration has an extensive list of references (at international level) for plants in quarries of various types (sand, gravel, limestone, marble) where industrial sludge containing clay is treated.

Application in Aggregate Recycling

Over the last 15 years, the increased focus on a circular economy has led to a growth in the recycling of aggregates from the demolition of buildings and old infrastructure. The recovery of these materials, for a “second life cycle”, makes it possible to reduce the excavation and crushing of virgin material and also to limit the amount of waste to be disposed of.

At the end of these recovery, washing and reclassification processes, the water contains fine solids with variable characteristics (depending on the recovered material) which require great care and attention for their treatment (sometimes requiring the addition of chemicals).

Equipment for this sector requires high reliability, robustness, suitability for heavy-duty operation and should be simple to use and maintain. Diemme® Filtration has long since developed several machine models corresponding to these needs for aggregate sludge treatment.