10+1 things to know when operating filter presses.

Episode 2 – Managing coarse solids for a more reliable filter press

Welcome to the second episode of our technical column, “10+1 things to know when operating filter presses.”

A space dedicated to sharing operational experiences, with the aim of promoting more informed design and more efficient operation of filtration systems.

Focus of the day: What are the risks associated with coarse solids?

Solid-liquid filtration is a process strongly influenced by the particle size distribution of the solids present in the suspension.

In general, larger particles promote drainage and reduce filtration times, while very fine particles slow down the dewatering process.

However, the presence of uncontrolled coarse solids (such as coarse sand, gravel, or small aggregates) can cause significant operational problems, including:

- Premature abrasion of pipes, valves, and especially filter cloths, resulting in a reduction in their useful life;

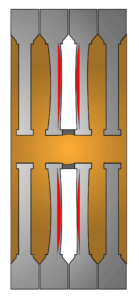

- Partial or total occlusion of the plate feed holes, resulting in uneven feeding of the chambers;

- Irregular cake formation and possible pressure differences between the plates, which can lead, in the worst cases, to mechanical failure of the plate pack.

In addition to generating direct costs for component replacement, such damage can result in long plant downtime.

A fundamental preventive measure

To prevent these problems, we recommend installing a mechanical screen upstream of the filter press, capable of retaining particles larger than a predefined threshold (e.g., 500 microns).

This simple precaution allows you to:

- Ensure a more homogeneous feed that is compatible with the design of the plates;

- Drastically reduce the risk of abrasion and clogging;

- Increase the overall reliability of the plant.

In the event of filter press breakage or malfunction, it is always advisable to perform a granulometric analysis of the sludge to check for the presence of out-of-specification solids, often attributable to deficiencies or irregularities upstream of the dewatering plant.

An essential principle that should not be overlooked

The filter press works optimally only if fed with a suspension consistent with its design characteristics.