The Diemme Filtration internal laboratory is much more than just an analysis center: it is a strategic asset for the company and the fundamental starting point for every plant project. Here, customized, high-performance solutions take shape, thanks to the presence of cutting-edge equipment and highly specialized technicians.

For this reason, the laboratory is the heart of the company’s innovation and R&D activities and, at the same time, an important resource for technical support to customers.

Expertise and technology at the service of filtration

Our team, composed of doctors in industrial chemistry, PhDs, and process engineers, carries out in-depth characterizations and experiments on sludge and fluids from a wide range of sectors on a laboratory and industrial scale, testing real samples to determine the ideal filtration and thickening parameters.

Through a combination of laboratory and on-site testing at the customer’s plant, we are able to support you from the early stages of feasibility studies and, in detail, to:

- Thoroughly analyze the chemical and physical characteristics of the samples

- Reproduce the filtration and thickening processes in the laboratory

- Provide useful data for plant sizing

- Validate the expected performance of the machinery

Our analytical and fluid dynamics expertise, combined with our ability to develop customized tests, allows us to:

- Optimize our customers’ production processes

- Select the most effective plant solutions

- Guarantee the expected performance of the machinery supplied

All work is carried out in direct dialogue with the customer, creating a shared technical path aimed at maximizing the efficiency of the final plant.

A comprehensive and scalable testing process

Our methodological approach is divided into several phases and allows us to accurately simulate the industrial process, collecting fundamental data for technical optimization and plant sizing.

1. Sample preparation

The sampling and sample preparation process is crucial for the quality of the data obtained.

- Collection of representative samples that accurately reflect the characteristics of the entire batch, taking into account product variability and assessing the need to test worst-case scenarios;

- Mixing and homogenization, if necessary, to reduce internal variability between subsamples;

- Simulation of the screening and dimensional classification process;

- Possibility of grinding the sample using a laboratory-scale rod mill in order to reduce the particle size and obtain a fine, uniform material.

Watch the video “Wonder Lab”

2. Basic physical characterization

Preliminary analyses to describe the main physical properties of the sludge:

- Sample density (total and/or solid fraction);

- Total solids and suspended solids content;

- TDS (Total Dissolved Solids) in the liquid phase;

- pH and electrical conductivity;

- LOI (Loss on Ignition) to estimate organic/volatile content;

- Particle size distribution.

3. Advanced chemical analysis

We use high-precision instruments for composition analysis:

- XRF (X-ray Fluorescence) for determining the elemental composition of the sample;

- XRD (X-ray Diffraction) for identifying crystalline phases and studying mineralogical structure.

4. Rheological analysis

We evaluate the behavior of the material under mechanical stress:

- Yield stress curves (sheared and unsheared) as a function of solid concentration, to determine the minimum stress required for flow (e.g., pumpability);

- Viscosity measurements to define the fluid dynamic behavior of the mud.

5. Geotechnical characterization

Tests aimed at describing the physical and mechanical behavior of sludge depending on its moisture content. These analyses are essential for assessing the stability of stacked cakes, their suitability for transport, handling, or confinement.

- Atterberg limits, to identify the transitions between solid, plastic, and liquid states;

- Compaction curves, to determine the optimum moisture content and maximum achievable density;

- Transportable moisture limit, beyond which the material can no longer be handled safely.

6. Laboratory-scale testing

We use bench-scale equipment (filter press and/or thickener) to simulate real industrial process conditions.

▸ Thickening test

- Screening and selection of flocculants;

- Optimization of the sludge dilution system in the feedwell, when necessary;

- Optimization of inlet flow rates and thickener diameter;

- Characterization of outlet flows (underflow and overflow).

▸ Filtration test

- Definition of process parameters (pressure, flow rate, cycle times);

- Characterization of the cake (thickness, residual moisture);

- Analysis of the filtrate (turbidity, residual solids);

- Washing efficiency curves;

- Selection of optimal filter media.

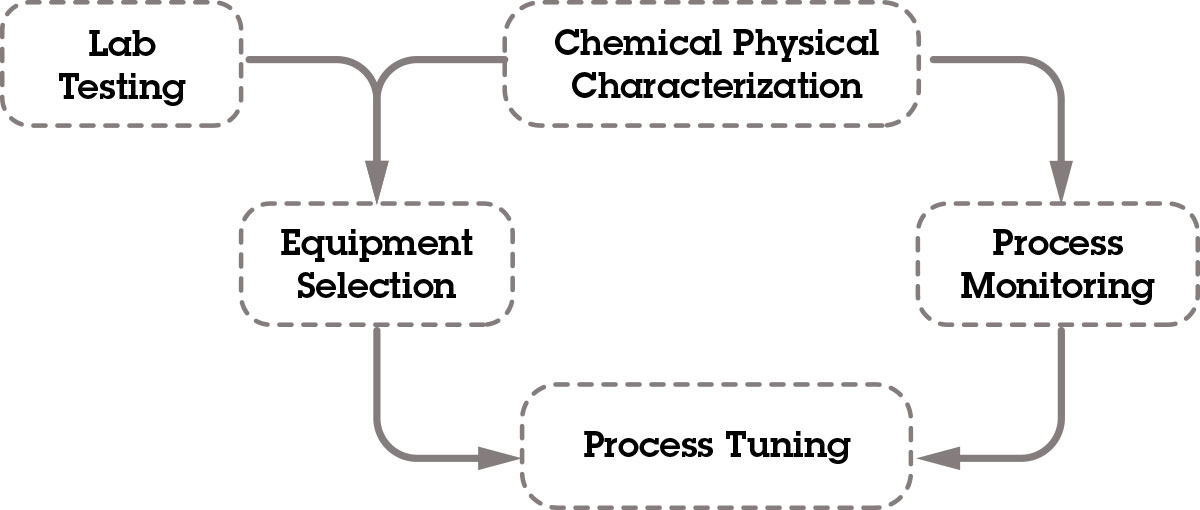

7. Integrated approach to design

The data collected is integrated into a process shared with the customer:

- Scalable data collection for final plant sizing;

- Advanced fluid dynamics analysis to simulate different operating scenarios and identify process trends;

- Sharing and comparison of results with a view to co-design;

- Possibility of performing on-site pilot tests thanks to the use of mobile units;

- Final validation of process parameters before plant construction.

Our laboratory,

the basis for customized solutions

In addition to testing activities in support of projects, the laboratory is also the hub of internal innovation: here, new technological solutions are developed and tested to anticipate market needs, improve plant performance, and optimize industrial processes.