From time to time, certain events bring us back to the core of a conversation we should never stop having. Over the past few years, both Diemme Filtration and many others have shared reflections on tailings safety and the role of dry stacking technologies. Recent news from Andavilque 1, in Peru, has revived this dialogue in a powerful and emotional way.

We want to be clear: we are not here to place blame. We don’t know what went wrong in that specific case, and it’s not our role to judge. But events like this remind us that, as an industry, we must continue to question what more can be done, because they leave no one indifferent.

Progress Is Happening, But We’re Not There Yet

To be fair, awareness has grown significantly. Mining companies, governments, and regulatory bodies have shown increasing concern for environmental and human safety in the past decade. The pace of change is accelerating but challenges remain.

One of the biggest barriers is still economic: capital expenditure (CAPEX) often dominates decision-making, even when safer alternatives exist. This short-term focus can slow down the adoption of transformative technologies.

A Proven Alternative: Dry Stacking

Tailings dewatering through filtration has evolved into a mature, robust, and highly adaptable solution. Unlike conventional tailings dams, dry stacking virtually eliminates the risk of catastrophic failure. It also reduces water usage, facilitates progressive rehabilitation, and improves environmental compliance.

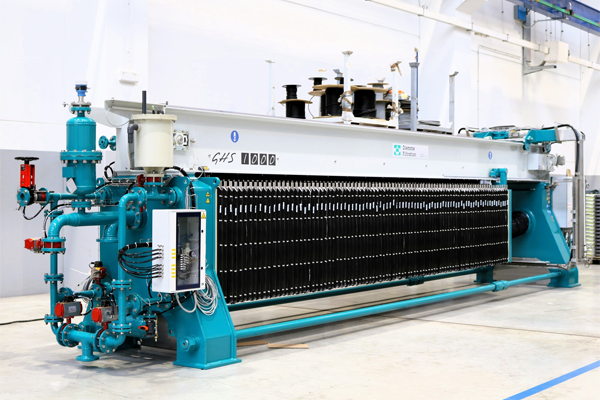

At Diemme, we’ve seen this potential become reality. Our GHT5000F Domino, the world’s largest filter press for tailings, has been fully operational since December 2022. Other large-scale machines are now in delivery and start-up phases.

These projects demonstrate that dry stacking can be implemented across a wide range of geographies and climates, from tropical to arid, from high-altitude to coastal, and adapted to different tailings compositions.

Every Case Deserves Its Own Study

The success of a dry stacking project depends on thorough planning:

- clear performance targets

- detailed tailings characterization using physico-chemical analysis

- laboratory-scale testing

- and, when needed, pilot-scale trials.

There is no universal recipe but there is a process. And it works.

Let’s Not Compare Tragedies, But Let’s Keep the Same Energy

When aviation tragedies occur, the response is often swift and decisive. Rightly so. When tailings dam incidents result in similar loss of life, the response, while improving, is still more fragmented, and often more focused on remediation than prevention.

The comparison is not about blame, it’s about urgency and mindset. Because we do have tools and knowledge available to prevent the next disaster.

A Call for Collective Responsibility

At Diemme Filtration, we are committed to offering solutions that help reduce risk and protect communities. We’re not here to claim that filtration is always the answer but we are here to say it deserves a serious, open-minded evaluation every time.

Mining is essential. So is making it safer for people, for the planet, for the future.

Let’s keep the conversation going. Let’s keep learning, adapting, and improving together.