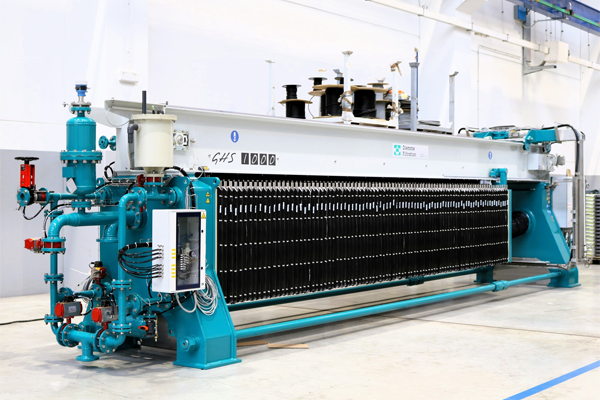

At our plant, the commissioning department is always buzzing. These days, a GHS 1000 filter press is undergoing final testing, ready to be shipped to Peru, where it will go into operation within a chlor-alkali plant.

Although not among the models most frequently in the spotlight, the GHS fully represents the strength of our approach: a broad, modular product range designed to adapt to extremely diverse application contexts, even the most challenging.

The GHS is a push-to-close high beam filter press, a configuration designed to minimize the parts of the frame in contact with the product. This feature makes it ideal for heavy-duty applications and corrosive environments, where reliability and durability make all the difference.

Every machine that leaves our commissioning department is the result of a shared process with the customer, made up of listening, technical expertise and tailored solutions.

Do you have a project looking for the right filtration solution?

Our team is ready to support you in developing the technology best suited to your needs. Contact us: we will build the most effective answer together.