10+1 things to know when working with filter presses.

Episode 1 – Correct positioning of the filtrate tank

Welcome to the first episode of our new technical column, “10+1 things to know when working with filter presses.”

A simple, practical, and straightforward space where we share experiences gained in the field, including those arising from past mistakes that are worth recognizing, understanding, and not repeating.

Like many initiatives promoted by Diemme Filtration, this one also has a clear objective: to spread technical knowledge in order to raise the general level of expertise in the solid-liquid filtration sector.

We are convinced that only by sharing practical knowledge we can build more effective, simpler, and better-designed systems.

Focus of the day: Where to position the filtrate tank?

It seems trivial. In reality, it is one of the biggest design pitfalls, often underestimated.

The first principle to remember is simple: the filtrate descends by gravity.

For this reason, the maximum level of liquid inside the collection tank must always be below the filter press support surface.

Unfortunately, this is not always the case.

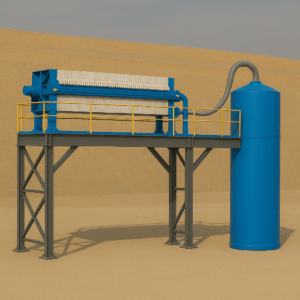

Over the years, we have seen cases where the filtrate tank was installed at the wrong level, often equal to or even higher than that of the filter press, as shown in the deliberately “incorrect” image generated by artificial intelligence.

The result? The filtrate does not flow properly, creating accumulations, back pressure, and malfunctions.

To solve the problem, it has often been necessary to resort to expensive and complex solutions, such as:

- Intermediate collection wells

- Boost pumps

- Backflow valves

- Additional automation systems

Solutions that could have been avoided altogether with a simpler layout that better respects the basic principles of plant design.

A basic principle not to be forgotten

When designing the system, it is essential to never lose sight of the laws of physics and the real dynamics of operation.

The filtrate is often mixed with drips from multiple points (frame, drip trays, drains, etc.): poor collection design means complicating your life from the outset.