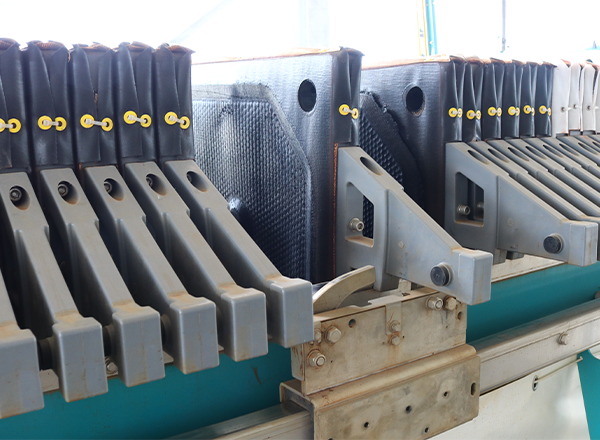

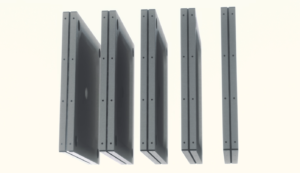

When it comes to filter press filtration, the choice of filter plates is crucial and generally falls into two main types:

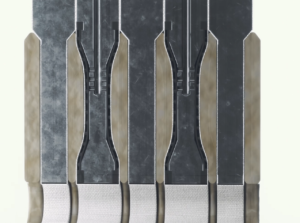

- Recessed Plates – or Fixed Chamber

- Membrane Plates – equipped with plastic membranes on the filtration surface that allow for additional cake compression

The selection between these types depends on the chemical and physical characteristics of the slurry and specific process requirements.

The recessed plate configuration is the more traditional setup. Here’s how it works:

- The slurry is pumped into the chambers, and only the pump pressure compacts the cake.

- Residual moisture in the cake depends solely on this pump pressure.

This setup is often chosen because it’s:

- Simpler, with fewer auxiliary components needed for operation

- More cost-effective (lower capital expenses)

- Statistically more durable, with fewer risks of plate breakage over time

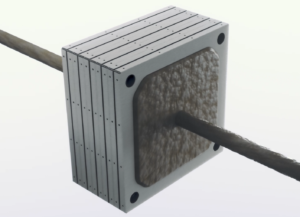

Membrane Plates: For Specialized Needs

In cases where the recessed plate configuration doesn’t meet specific residual moisture targets, membrane plates are considered. Here’s the difference:

- The initial compaction occurs with pump pressure, but in the final stage, the membrane presses the cake further to achieve desired dryness levels.

Membrane plates are ideal when:

- The slurry has poor filterability, risking thin cake formation.

- Very low residual moisture targets are needed.

- Cake washing is required, with high recovery of valuable materials or removal of contaminants.

- Permeable cakes require low residual moisture levels and can be paired with air-blowing to optimize dryness.

Pros and Cons: Recessed vs. Membrane Plates

- System simplicity

- Fewer auxiliary components

- Statistically more durable

- Lower cost

- Higher flexibility for poorly filterable products

- Improved efficiency in cake washing processes

- Ability to achieve higher dry residue targets

- Enhanced drying when paired with air-blowing

In conclusion, while recessed plates offer simplicity and lower costs, membrane plates provide added flexibility and efficiency for complex filtration needs. Selecting the right configuration can significantly impact the performance and cost-effectiveness of your filtration process.

If you are curious to learn more about this topic, feel free to reach out, and I’ll be happy to provide any additional information.

Dino Ibba – Regional Sales Director – USA & Canada

dino.ibba@diemmefiltration.com

+39 366 69 75 963